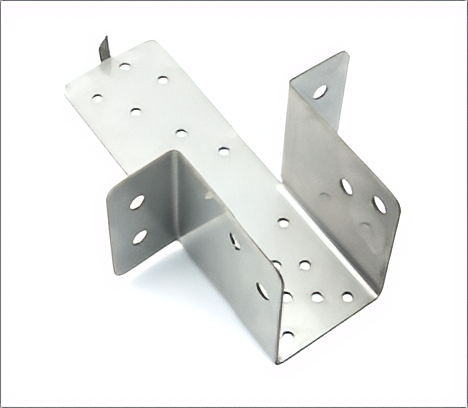

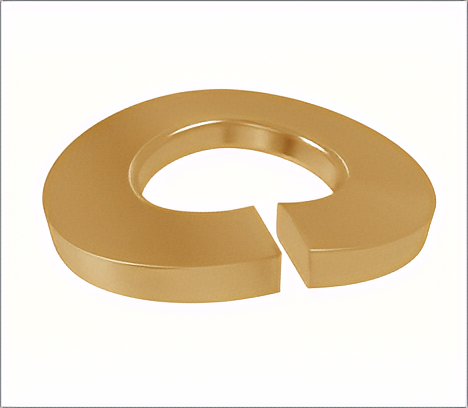

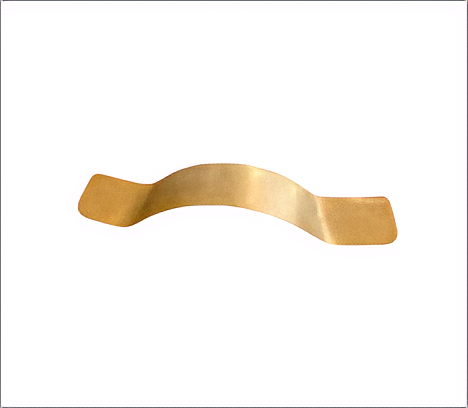

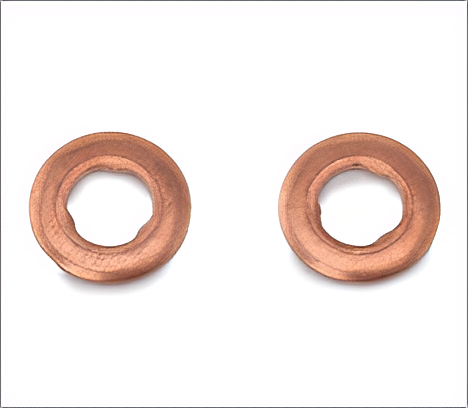

Stamped, punched, bent, welded parts

Sheet Metal Components are manufactured with high precision using advanced stamping, punching, bending, welding, and laser cutting technologies. These components are designed for strength, durability, and dimensional accuracy to meet demanding industrial requirements.

Our expertise in sheet metal processing allows us to deliver brackets, enclosures, mounting plates, clamps, and cable trays tailored to client specifications. Every part undergoes stringent inspections to ensure reliability and compliance with international standards.

Applications

Sheet metal parts play a critical role across multiple sectors requiring robust and customized solutions.

Automotive

Electrical Panels

Key Features

- Advanced stamping, punching & bending

- Laser cutting for high precision

- Strong welds and surface finish

- Custom designs as per client drawings

- Suitable for structural and decorative uses

- Strict dimensional accuracy checks

Product Gallery

Frequently Asked Questions

We use high-grade steel, aluminium, copper, and other alloys depending on customer requirements and application needs.

Yes, we specialize in customized solutions, delivering components as per client drawings, 3D models, and technical specifications.