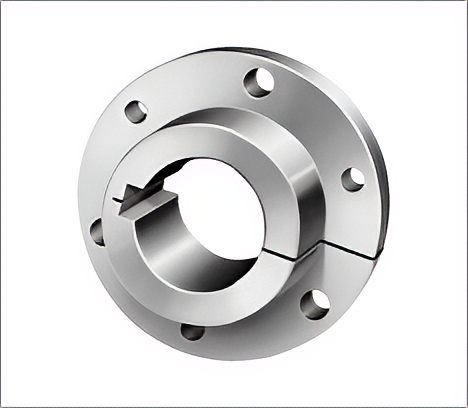

CNC, VMC turned & milled parts

Deep Enterprise manufactures high-accuracy precision machined components designed to meet the most demanding specifications. Every part is developed from customer-provided drawings and 3D models, ensuring absolute dimensional accuracy and reliability.

Our expertise spans a wide range of applications including automotive, sensor housings, instrumentation, pneumatics, electrical, and general engineering industries. With CNC and VMC technology, along with advanced turning, milling, threading, knurling, broaching, and drilling processes, we deliver unmatched precision at scale.

Applications

Our machined components are widely used across industries where quality and tolerance are non-negotiable:

Automotive

Instrumentation

Key Features

Every component is built with consistency, reliability, and global standards of precision:

- Diameter range: 3 mm – 150 mm

- Length range: 5 mm – 1000 mm

- Materials: Brass, Stainless Steel, Mild Steel, Aluminium, Copper

- Processes: CNC, VMC, Turning, Milling, Threading

- Advanced checks: 100% dimensional testing

- Documentation: SPC & PPAP/APQP support

Product Gallery

Frequently Asked Questions

Here are some quick answers to commonly asked questions regarding our precision machined components:

We can machine components up to 150 mm in diameter and 1000 mm in length with high precision.

Yes, all products come with 100% dimensional checks, SPC analysis, and PPAP/APQP documentation support.

Our precision machined components are widely used in automotive, pneumatics, electrical, instrumentation, and general engineering industries.