Threaded Studs for Critical Joints

Deep Enterprise manufactures precision threaded studs used wherever high-strength, repeatable bolted joints are required. Studs enable easy assembly and disassembly, stable preload, and accurate alignment for flanges, housings, manifolds, and structural components.

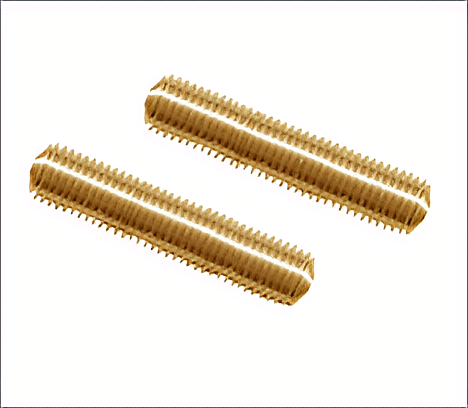

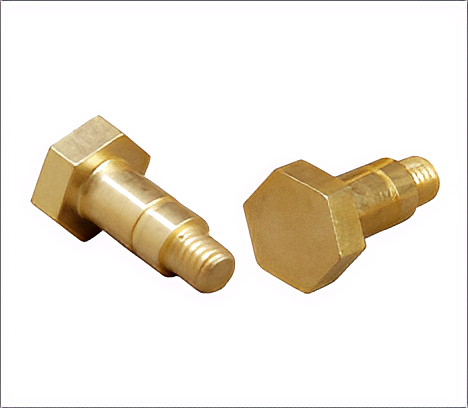

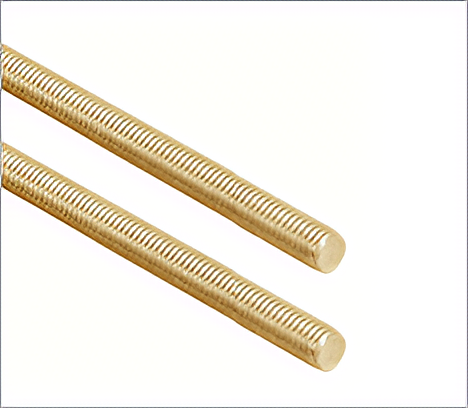

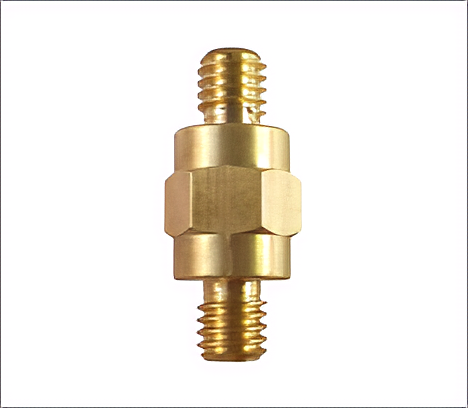

Our range includes full-thread studs, double-end studs, tap-end studs, weldable studs, and special custom designs. Each stud is produced with controlled thread geometry, straightness, and surface conditions to maintain joint integrity under dynamic loads and temperature cycles.

Applications

Studs from Deep Enterprise support a wide range of industrial fastening and assembly requirements:

Automotive & Engines

Industrial & Power Equipment

Flanges & Piping

Custom OEM Assemblies

Key Features

Our studs are engineered for safe load transfer, repeatable tightening, and straightforward maintenance:

- Types: full-thread studs, double-end studs, tap-end studs, weld studs and customised variants.

- Threads: Metric, UNC, UNF, BSP and special threads as per drawing or standard.

- Materials: carbon steel, alloy steel, stainless steel and other grades as per strength and environment.

- Length and thread engagement tailored to flange thickness, nut style, and required preload.

- Surface treatments such as zinc plating, phosphating, blackening, or custom coatings to resist corrosion.

- Dimensional and visual inspection with sampling plans, plus traceability and documentation support when needed.

Design & Customisation

Deep Enterprise can design and supply studs aligned to your joint calculations and torque procedures. We consider flange or housing geometry, nut types, gasket compression, and service access while finalising stud lengths and thread details.

Special features such as center points for alignment, wrench flats, identification grooves, and marking can be included to support assembly and maintenance teams at the shop floor or in the field.

Product Gallery

Frequently Asked Questions

Key details about our stud manufacturing and supply:

We support both. Studs can be manufactured as per applicable standards or fully to your drawings and specifications. Lengths, thread details, and tolerances are finalised in line with your application needs and documentation requirements.

Manufacturing routes and handling are defined to limit distortion, while straightness and critical dimensions are monitored through sampling and dedicated gauges. For demanding joints, additional checks can be added by mutual agreement.

Yes. Chemical and mechanical test certificates, heat number traceability, and batch identification can be provided where required, supporting critical projects and compliance standards in power, process, and automotive sectors.