Precision Engineered Screws

Deep Enterprise manufactures a wide range of precision screws built for reliable clamping, assembly, and serviceability. From small electronic screws to structural fasteners, every part is produced to drawing or standard with consistent threads and head geometry.

Our capabilities cover machine screws, self-tapping screws, self-drilling screws, and special-purpose designs for metal, plastic, and composite assemblies. Controlled processes, verified threads, and surface finishes help your assemblies perform reliably in the field and during repeated service operations.

Applications

Our screws are used across multiple industries where repeatable fastening and clean assembly are critical:

Automotive & Assemblies

Electrical & Panels

Industrial & Machinery

Electronics & Consumer

Key Features

Our screw range is designed to balance ease of assembly, strength, and long-term performance:

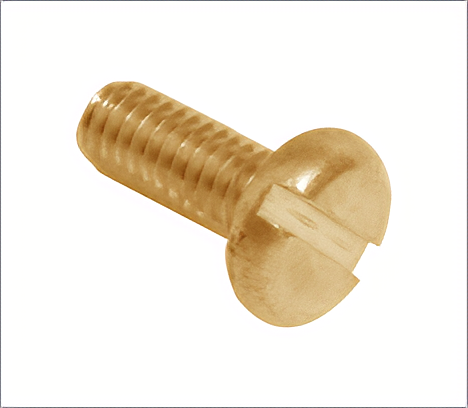

- Types: machine screws, self-tapping screws, self-drilling screws, and special profile screws.

- Head styles: pan, CSK, cheese, hex, socket, flange head and customised designs.

- Drives: slotted, Phillips, Pozidriv, hex, Torx and combination drives available.

- Threads: Metric, UNC, UNF, BSP and custom pitch/length combinations.

- Materials: steel, stainless steel, brass and other alloys with project-specific plating or coating.

- Batch-level inspection with thread gauges, head tolerance checks, and optional torque tests.

Design & Customisation

Deep Enterprise supports standard as well as fully customised screw designs. We can match existing samples, develop new head styles for branding, or optimise length and thread engagement based on your assembly trials. Special features such as points, under-head profiles, captive sections, and driving recess variations can be integrated on request.

Our team works closely with OEM and engineering teams to ensure that material grade, coating, and tolerance stack-up align with your functional, corrosion, and assembly requirements.

Product Gallery

Frequently Asked Questions

Some common queries regarding our screw range:

Yes. We can develop screws based on your samples, drawings, or OEM references, aligning head type, thread form, and coating so that they fit seamlessly into your current assemblies and service manuals.

We offer stainless steel grades and specialised coatings that improve resistance against moisture, chemicals, and coastal environments. Options can be selected based on your life-cycle and salt-spray test requirements.

Threads are checked with GO/NO-GO gauges and visual inspection, while head dimensions and drive features are monitored through sampling plans. Additional documentation and PPAP/APQP support can be provided when required.