Bulkhead & Tank Connectors

Deep Enterprise manufactures robust tank connectors engineered to create reliable, leak-tight connections through tank walls, reservoirs, and enclosures. Each connector is designed around your drawing, media type, and pressure requirements to ensure long-term performance in demanding environments.

Our tank connectors are widely used for suction, return, drain, and level ports in hydraulic power units, coolant tanks, filtration modules, and industrial skids. With controlled machining of sealing faces and threads, we deliver stable performance under vibration, pressure cycles, and varying temperature conditions.

Applications

Our tank connectors support a wide spectrum of hydraulic, pneumatic, and process installations:

Hydraulic Reservoirs

Cooling & Filtration Units

Process & Utility Tanks

Custom OEM Modules

Key Features

Tank connectors are developed to simplify installation while maintaining dependable sealing and structural strength:

- Bulkhead-style construction for secure mounting through sheet metal and fabricated tanks.

- Available in straight, 90° and multi-port designs to match routing and layout constraints.

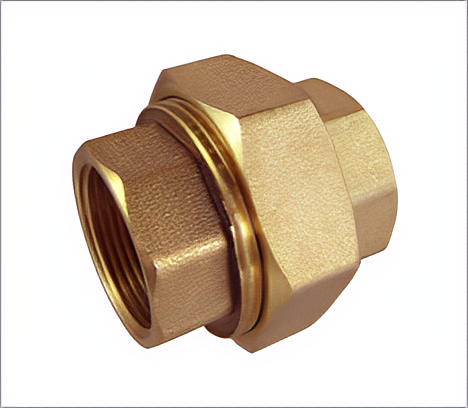

- Materials offered: carbon steel, stainless steel, and brass based on media and environment.

- Standards: DIN, BSP, UNF, JIC, ISO for threads and connection interfaces.

- Designed for both pressure and return lines with appropriate safety factors and wall thickness.

- Sealing options include O-ring grooves, metal-to-metal faces, and gasket-based interfaces.

Design & Customisation

Beyond standard configurations, Deep Enterprise collaborates with design and maintenance teams to develop tank connectors that align with your fabrication practices and service requirements. Port sizes, thread types, mounting nut geometry, and gasket selection are fine-tuned to suit tank material, wall thickness, and access conditions.

We can integrate features such as lock-nut flats, wrenching surfaces, level sensor ports, and integrated transition to hoses or pipes, all backed by controlled machining and documented inspection plans.

Product Gallery

Frequently Asked Questions

Answers to common questions regarding our tank connectors:

Yes. We can work with your tank drawings or samples to align connector geometry, thread type, and sealing concept with existing cut-outs, wall thickness, and fabrication practices, reducing changes in your current design.

Depending on the application, we can provide zinc-plated, nickel-plated, stainless steel, or other corrosion-protective options suitable for outdoor exposure, humid environments, or specific media compatibility requirements.

Leak integrity is validated through dimensional control of sealing faces, controlled torque and assembly conditions, and optional hydrostatic or pneumatic leak tests as per agreed test pressure and duration. Additional validation can be included for critical projects.