Pipe Fittings for Fluid & Air Lines

Deep Enterprise supplies engineered pipe fittings that ensure safe, controlled, and consistent flow in hydraulic and pneumatic circuits. Each fitting is produced to drawing, with tight thread integrity and sealing performance tailored to your media, pressure, and environment.

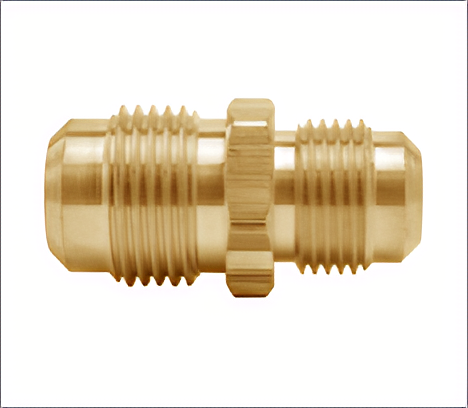

Our range covers elbows, tees, crosses, reducers, unions, couplings, caps, and plugs used to route, branch, connect, and terminate fluid and air lines. Whether you are building power packs, industrial skids, or plant pipelines, we deliver fittings that install easily, seal reliably, and integrate seamlessly with international thread and pipe standards.

Applications

These pipe fittings are used wherever hydraulic oil, air, water, or process media must be routed with reliability and repeatable performance:

Hydraulic Power & Lube Lines

Pneumatic & Utility Networks

Process & Industrial Piping

Custom OEM Assemblies

Key Features

Each pipe fitting is designed to deliver reliable performance in demanding field conditions:

- Nominal sizes from small-bore instrumentation lines to heavy-duty industrial piping.

- Available in elbows, tees, crosses, reducers, unions, caps, plugs, nipples, and couplings.

- Materials as per application: carbon steel, stainless steel, brass, and aluminium on request.

- Standards: DIN, BSP, UNF, JIC, ISO.

- Pressure ranges engineered to suit hydraulic, air, and utility applications with safety margins.

- Surface finishes such as zinc plating, phosphating, or custom coatings for corrosion protection.

Design & Customisation

Beyond standard fittings, we work closely with OEMs and project teams to develop pipe fitting designs that address layout constraints, media compatibility, and installation preferences. From special reducers and step-down connections to integrated ports and mounting features, our engineering team can adapt fittings to your exact requirement.

Tolerance stacks, thread engagement, sealing methods (metal-to-metal, elastomeric, or compound-based), and material grades are defined to align with your drawings, specifications, and approval procedures.

Product Gallery

Frequently Asked Questions

Some commonly asked queries about our pipe fittings for hydraulic and pneumatic systems:

We offer pipe fittings in multiple global standards including DIN, BSP, UNF, JIC, and ISO. The selection is finalised as per your drawing, region of use, and mating components.

Yes. We regularly develop custom elbows, step-down reducers, and special unions to match tight layouts, clearance needs, or integration with existing plant piping. Our team works directly with your engineering drawings and 3D models.

Leak performance is ensured through controlled machining of threads and sealing faces, selection of suitable materials and coatings, and validation with hydrostatic or pneumatic pressure testing as per agreed specification. Additional tests can be included for critical applications.