Engineered Hose Connection Solutions

Deep Enterprise designs and manufactures hose fittings that provide secure, durable connections between flexible hoses and rigid system components. Each part is produced with controlled barbs, profiles, and threads to maintain reliable sealing and retention under dynamic operating conditions.

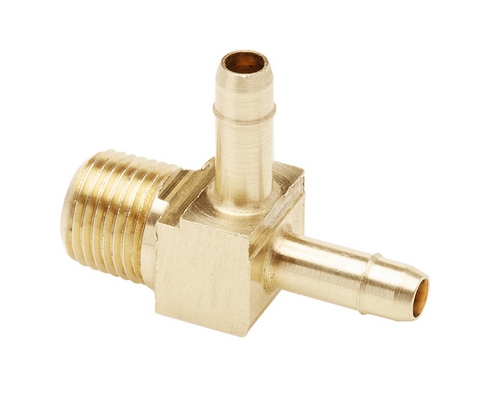

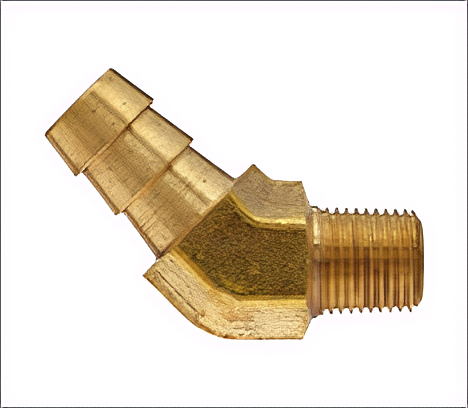

Our range covers straight, elbow, and multi-port geometries for hydraulic oil, air, water, and process media handling. Careful attention to bore transitions and internal pathways helps minimise pressure losses, reduce turbulence, and support consistent flow across the hose assembly.

Applications

Hose fittings from Deep Enterprise are used across a wide variety of fluid and air distribution systems:

Hydraulic & Industrial Equipment

Pneumatic & Utility Services

Key Features

Our hose fittings are developed to combine ease of assembly with long-term operating reliability:

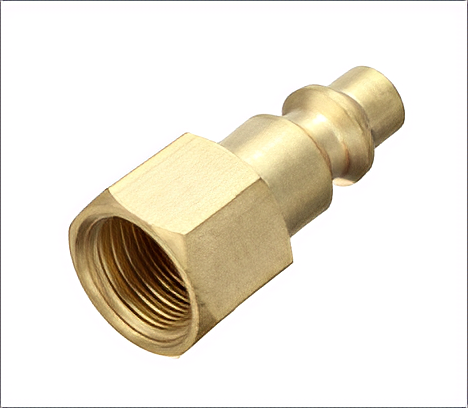

- Range includes hose tails, elbows, tees, reducers, and end connections for flexible hoses

- Profiles designed for strong grip with clamps, crimp ferrules, or screw-type hose clips

- Materials: Brass, Stainless Steel, Mild Steel, Carbon Steel depending on media and environment

- Thread options for integration with valves, manifolds, pumps, and cylinders

- Standards: DIN, BSP, UNF, JIC, ISO

- Protective surface treatments available for outdoor, marine, and corrosive conditions

Design & Customisation

We support OEMs and system integrators with project-specific hose fitting designs:

- Custom lengths, step-down bores, and special bend radii for compact routing

- Options to match hose ID/OD, wall thickness, and clamp style for secure retention

- Transition designs from hose to threaded, flanged, or push-in connections

- Part numbering, engraving, or marking as per your system and logistics needs

- Prototyping support for new platforms, with feedback-based optimisation of geometry

- Packing and kit preparation for assembly lines and aftermarket distribution

Product Gallery

Frequently Asked Questions

Answers to common queries regarding our hose fittings and their use in fluid systems:

Selection depends on hose size, media, working pressure, temperature, and connection type on the equipment. Share your hose specification and end-connection requirement, and we can propose a suitable fitting construction.

Yes. We offer various finishes such as zinc plating, nickel plating, and other protective coatings based on the corrosion category and aesthetic requirements of your project.

We can supply small batches for new development, pilot builds, and validation, followed by ramp-up to serial production volumes with consistent quality and documentation.