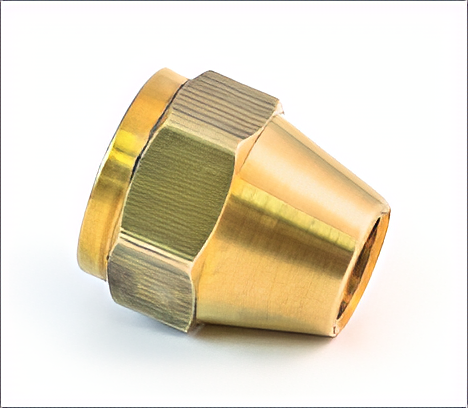

Precision Flare Tube Fittings

Deep Enterprise manufactures precision flare fittings engineered for robust, leak-tight tube connections in dynamic hydraulic and pneumatic environments. Designed for single and double flare configurations, each fitting is produced to achieve accurate seating angles and consistent clamping forces on metal tubing.

These fittings are ideal where vibration resistance, repeatable assembly, and serviceability are critical—such as fuel lines, brake circuits, refrigeration loops, and instrumentation panels. Controlled machining, uniform thread quality, and carefully finished sealing surfaces ensure dependable performance over prolonged operating cycles.

Applications

Our flare fittings are chosen wherever secure, serviceable tube connections are required:

Fluid & Fuel Lines

Refrigeration & Instrumentation

Key Features

Flare fittings are built to ensure repeatable assembly and stable performance under pressure and vibration:

- Types: nuts, sleeves, unions, tees, elbows, and adapter fittings for flared tubes

- Suitable for single and double flare tube ends depending on application

- Materials: Brass, Stainless Steel, Mild Steel, Carbon Steel for varied media compatibility

- Precisely machined cone and seat surfaces for consistent metal-to-metal sealing

- Standards: DIN, BSP, UNF, JIC, ISO

- Surface finishes tailored for corrosion resistance and aesthetic requirements

Design & Customisation

We support project-specific designs to align flare fittings with your tube routing and assembly practices:

- Configurations for different flare angles and tube wall thicknesses

- Adaptation to your existing tube OD/ID and tightening torque requirements

- Integration with manifolds, blocks, and transition fittings between flare and other joint types

- Options for part marking and batch traceability for OEM and aftermarket supply chains

- Assembly-friendly chamfers, hex sizes, and wrench flats for quick installation

- Packaged as per kit sets, line-wise assortments, or bulk supply as required

Product Gallery

Frequently Asked Questions

Helpful information on design, compatibility, and usage of our flare fittings:

Yes. We manufacture flare fittings as per your tube standards and tool specifications, ensuring they work seamlessly with your existing flaring tools, tube ODs, and seating angles.

Flare fittings are widely used in medium to high-pressure systems when properly selected for tube material, wall thickness, and operating pressure. We can support you with recommendations based on your working conditions.

Yes. We can develop pilot samples and trial lots for validation on your lines. After approval, we set up dedicated production and quality plans to support ongoing supplies.