Hydraulic & Pneumatic Line Fittings

Deep Enterprise manufactures a wide range of hydraulic and pneumatic fittings engineered for reliable, leak-tight performance in demanding fluid and air circuits. Each fitting is produced as per customer drawings and standards, ensuring accurate geometry and repeatable assembly in production environments.

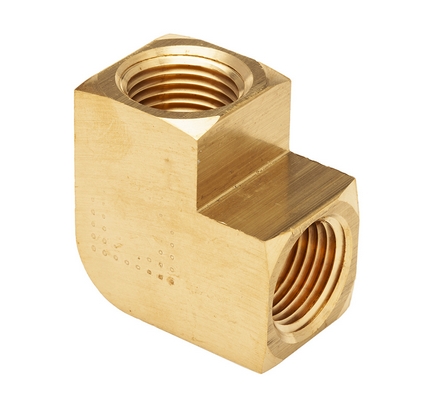

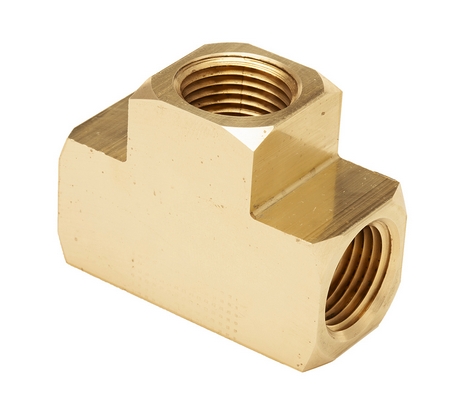

Our fittings range covers adapters, elbows, tees, reducers, unions, couplers, and custom connectors used in hydraulic power packs, pneumatic manifolds, industrial machinery, and EV cooling systems. With precise machining, controlled surface finish, and tested sealing performance, these fittings help maintain pressure integrity and system efficiency over long service life.

Applications

Our fittings are designed for high-performance hydraulic and pneumatic circuits across multiple industries:

Hydraulic Power Packs

Pneumatic Systems

Key Features

Fittings are manufactured to deliver consistent sealing performance and dimensional stability in every batch:

- Wide range of geometries: straight, elbow, tee, cross, bulkhead, and reducer fittings

- Materials: Brass, Stainless Steel, Mild Steel, Carbon Steel as per application

- Thread options: parallel, taper, internal & external threads with controlled tolerances

- Surface finishes: Zinc, Nickel, Phosphate, or custom coatings for enhanced corrosion resistance

- Standards: DIN, BSP, UNF, JIC, ISO

- 100% visual & dimensional checks on critical-to-quality parameters

Configurations & Design Options

Fittings can be customised to suit specific layout, pressure, and media requirements:

- Integration with manifolds, blocks, and adapter plates as per 2D/3D models

- Options for O-ring face seal, metal-to-metal seating, and compression-type sealing

- Compatibility with hoses, tubes, and rigid pipes in mixed assemblies

- Custom identification: laser marking, part coding, or batch traceability

- Pressure-tested and validated as per customer-defined test protocols

- Packaging options for line assembly, kit sets, or aftermarket supply

Product Gallery

Frequently Asked Questions

Some quick clarifications regarding our hydraulic and pneumatic fittings:

Yes. We manufacture fittings strictly as per your drawing or sample, matching thread forms, seating angles, and dimensional tolerances to DIN, BSP, UNF, JIC, and ISO standards where required.

We can supply fittings with Zinc, Nickel, Phosphate, or customer-specific coatings, validated through salt spray tests and visual inspections as per agreed specifications.

Yes. We support prototype and pilot quantities for new projects, followed by ramp-up to regular production volumes once designs are frozen and validated at your end.