Leak-proof Compression Fittings for Fluid & Air Lines

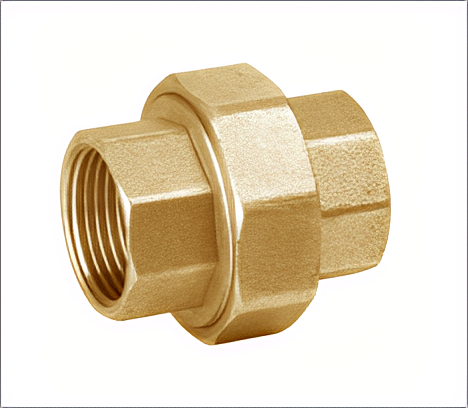

Deep Enterprise manufactures precision compression fittings engineered for leak-proof performance in hydraulic and pneumatic lines. Each fitting is produced as per customer drawings and specifications to ensure secure, vibration-resistant joints in demanding operating conditions.

Our compression fittings are designed for reliable fluid and air handling in critical applications such as hydraulic machinery, pneumatic control circuits, EV cooling manifolds, process instrumentation, and industrial automation. With support for international thread and tube standards, we deliver consistent, repeatable performance across every batch.

Applications

Our compression fittings are used wherever safe, serviceable, and leak-free joints are required in metal, plastic, or composite tubing systems:

Hydraulic Systems

Pneumatic Circuits

Process & Instrumentation

EV & Cooling Manifolds

Key Features

Each compression fitting is designed for robust sealing performance, repeatable assembly, and long service life under pressure and vibration:

- Tube OD range: As per customer requirement (metric & imperial options)

- Thread standards: DIN, BSP, BSPT, UNF, NPT, JIC, ISO

- Materials: Brass, Stainless Steel, Mild Steel, special alloys on request

- Finishes: Zinc, Nickel, Tin, HDG, or application-specific coatings

- Testing: Hydrostatic & pneumatic pressure tests with traceable reports

- Documentation: Dimensional inspection, PPAP/APQP, and test certificates on request

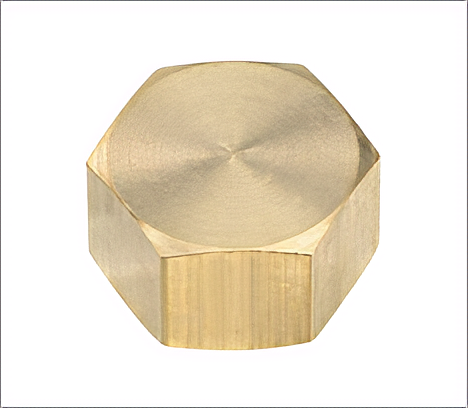

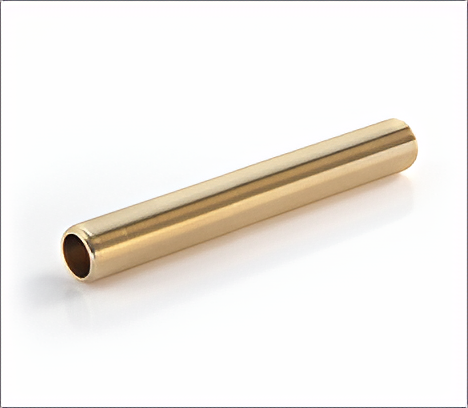

Product Gallery

Frequently Asked Questions

Here are answers to common questions regarding our hydraulic and pneumatic compression fittings:

Pressure rating depends on tube size, material, and application. We manufacture compression fittings suitable for standard hydraulic and pneumatic pressures and can validate performance through hydrostatic and pneumatic testing as per your specification.

Yes. We support a wide range of international thread and tube standards, including DIN, BSP, BSPT, UNF, JIC, NPT, and ISO. Our team can also develop custom variants based on your legacy drawings or reference samples.

We can supply dimensional inspection reports, pressure test certificates, and PPAP/APQP documentation as required. Salt spray and corrosion-resistance tests can also be conducted based on your specification or standard.