Who We Are

Your Trusted Partner for Precision Components

Established in 2000 in Jamnagar, Gujarat, Deep Enterprise has grown from a small workshop into a global OEM partner for precision-engineered brass, copper, aluminium, stainless steel and alloy components. With integrated expertise in machining, forging, surface treatment and quality validation, we manufacture parts that perform under the toughest industrial standards.

Our vision is to become a world-class partner for precision components in global markets. Our mission is to deliver precision, innovation and reliability through customer-focused engineering. Guided by our core values — Integrity, Excellence, Efficiency, Collaboration and Commitment — we ensure that every project reflects our promise of consistency and quality.

Infrastructure

Our state-of-the-art facilities integrate CNC machining, forging, finishing, compliance, and packaging solutions. Every unit is designed to ensure accuracy, repeatability, and scalability for both prototypes and high-volume orders.

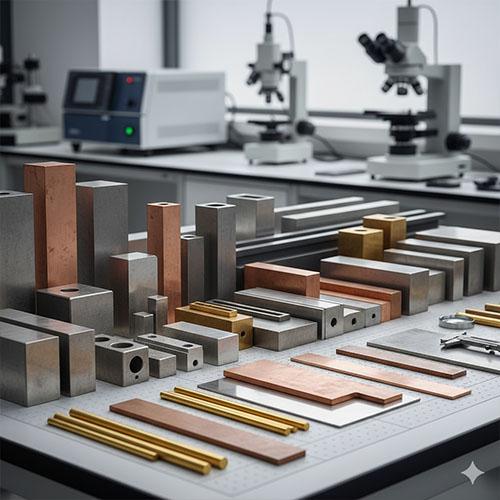

Materials Expertise

CNC Machining Range

Forging Capabilities

Surface Finishes

Surface Treatments

Compliance & Docs

Assembly Units

Export Packaging

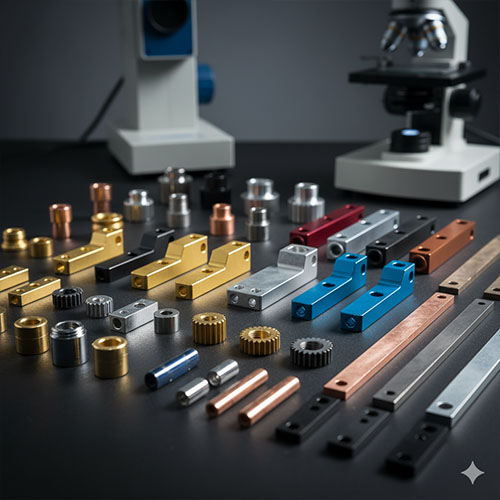

Our Product Range

High-Precision Components

Across Every Sector

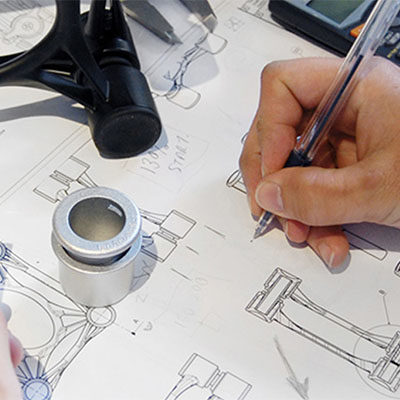

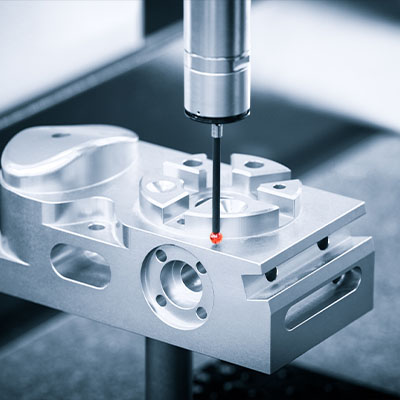

Our Process

Precision Brass Components

Manufacturing Workflow

Design & Prototyping

Material Preparation

Machining

Inspection & Dispatch

Industries We Serve

Description

Precision-engineered components for the EV and Industrial Power Systems sector — designed for efficiency, conductivity, and performance under dynamic loads.

Description

Electrical and power-distribution hardware supporting safe and efficient current flow in control panels, substations, and renewable energy setups.

Description

Reliable, leak-proof fittings and manifolds for hydraulic and pneumatic control systems across industrial automation and machinery applications.